Gemstone Oiling & Resin Filling Machine

Professional gemstone treatment machine designed to enhance clarity and durability through safe high-pressure oiling and optional resin filling. The chamber is constructed from stainless steel, featuring temperature control, a timer function, a cooling fan, and a compact, durable design, delivering reliable performance for emerald and other gemstone treatments. Available in two variants: Oiling + Resin or Oiling-Only, and supplied with step-by-step SOP and after-sales support.

Overview

The Gemstone Oiling & Resin Filling Machine is a professional solution for gemstone manufacturers, labs, and jewelry professionals. Controlled vacuum and heat allow oil or resin to penetrate deep into fractures and pores, enhancing clarity and reinforcing gemstones. The system is constructed using stainless steel and fits easily into workshops and production units.

Choose from two variants: a dual Oiling + Resin system or an Oiling-Only system.

Key Features

- Durable SS304 stainless steel chamber

- Safe high-pressure operation optimized for gemstone treatments

- Typical emerald working range: 6000–7000 PSI, safe maximum below 9000 PSI

- Digital temperature control up to 100 °C

- Timer function

- Vacuum integration for deep oil or resin infiltration

- Compact footprint suitable for continuous use

- Step-by-step SOP and after-sales support included

Technical Specifications

| Chamber Capacity | ~140 ml (65 mm height × 52 mm diameter) |

| Vacuum Level | −650 to −730 mmHg |

| Temperature Range | Up to 100 °C |

| Timer Range | Up to 999 minutes |

| Recommended Pressure Range | 6000–7000 PSI for Emeralds and most other stones |

| Maximum Pressure | 9000 PSI |

| Power Supply | 220 V / 110 V |

| Construction | SS304 stainless steel, sealed chamber |

| Dimensions | 340 × 215 × 306 mm |

| Weight | ~18 kg |

What's Included

- Main chamber with digital temperature & timer control

- Threaded oiling lid with sealing O-rings, pressure gauge (Rated 10000 PSI), and valve (Rated 10000 PSI)

- Oil suction kit

- Extra O-rings and seals

- 4 foundation bolts

- 2 tightening levers

- Power cable

- User Manual & SOP guide

- Extras for Oiling + Resin variant: 2-stage 1/4 hp vacuum pump and acrylic resin lid with vacuum gauge & valve

Applications

- Oiling treatment for emeralds and other porous gemstones

- Resin filling for fracture reinforcement (Oiling + Resin variant)

- Suitable for both natural and synthetic gemstones

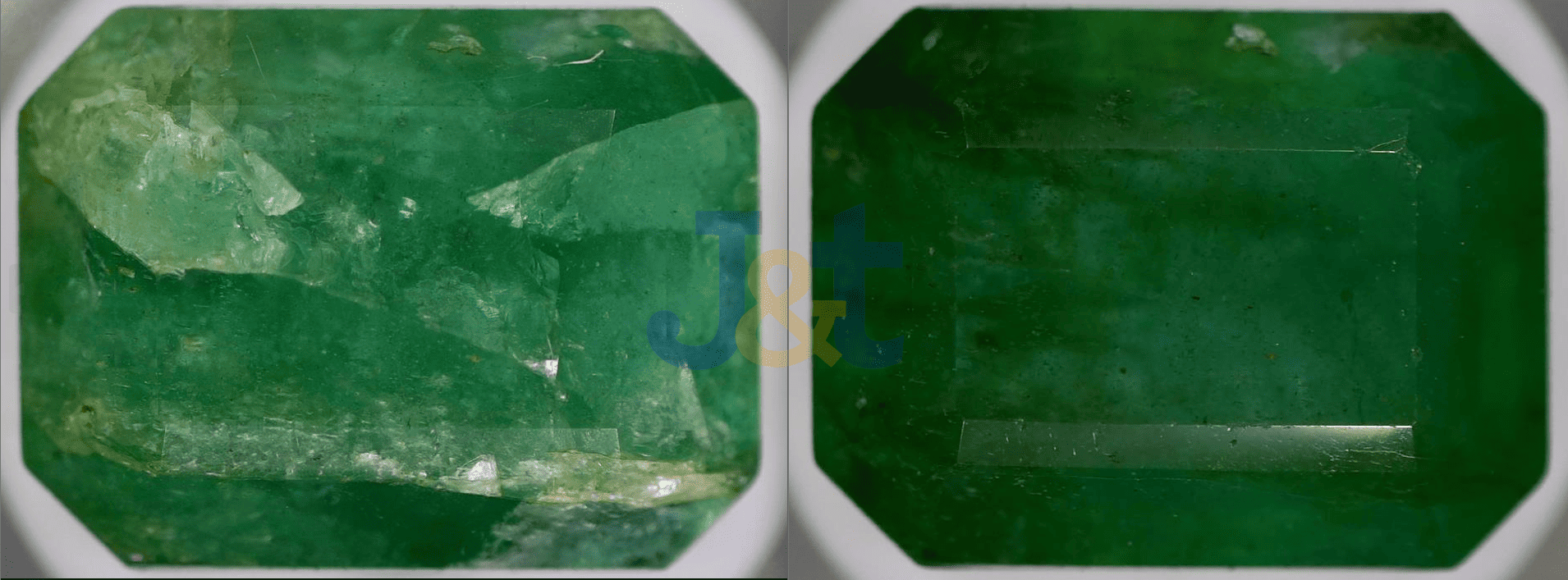

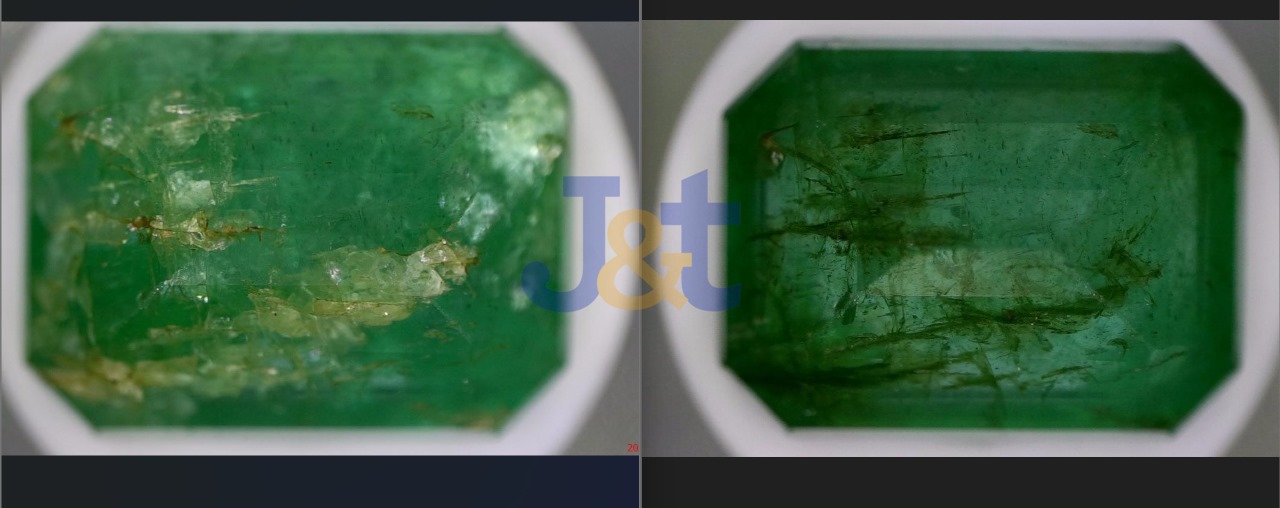

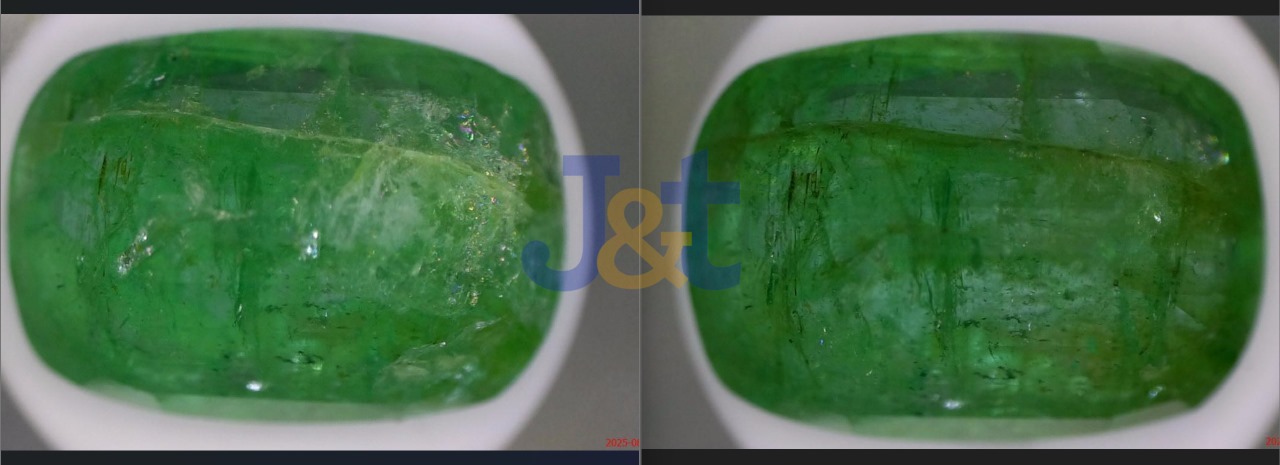

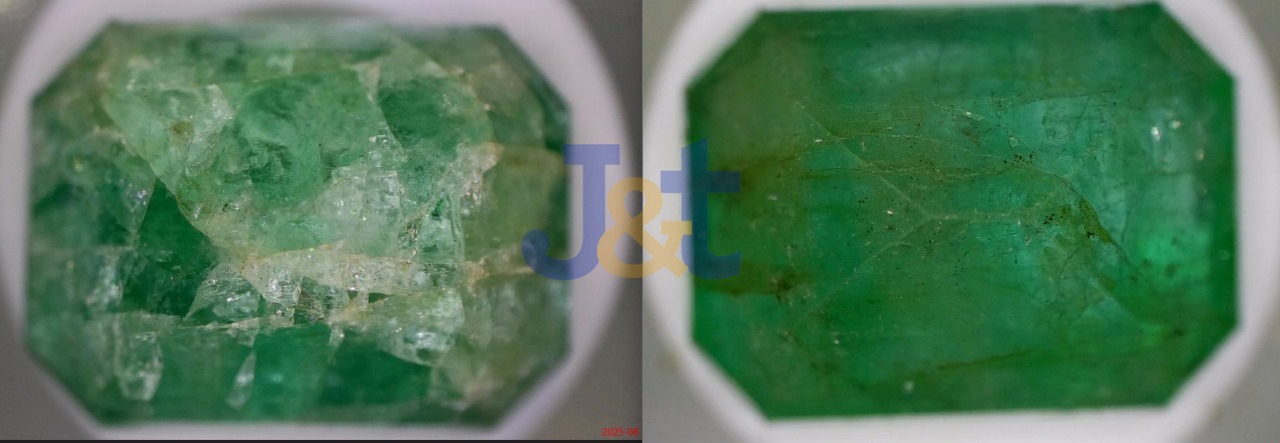

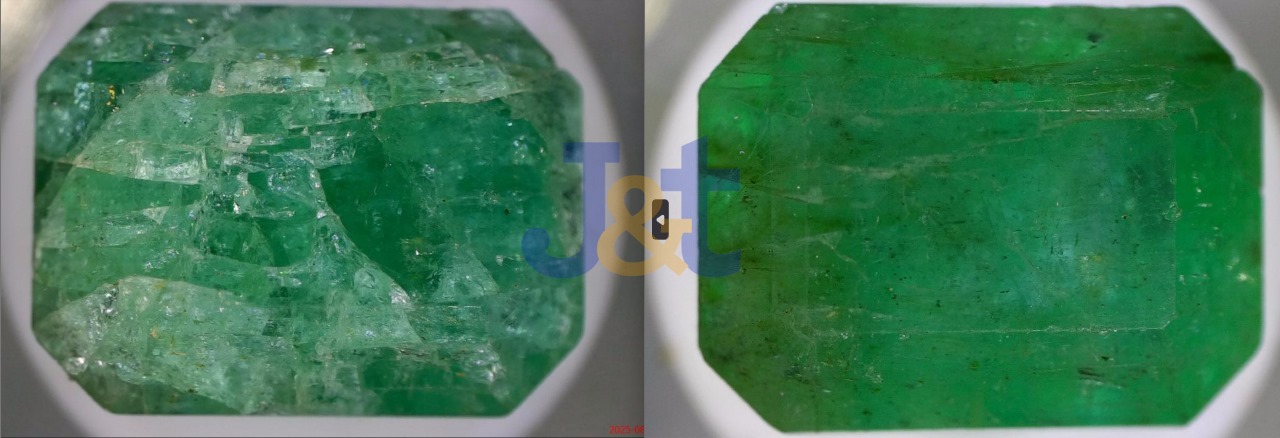

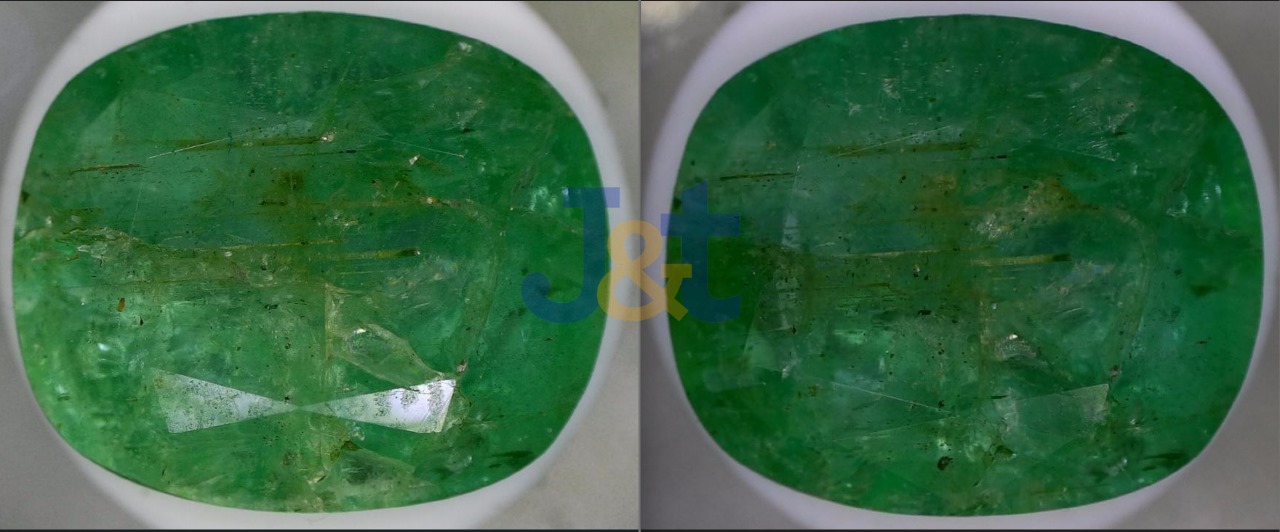

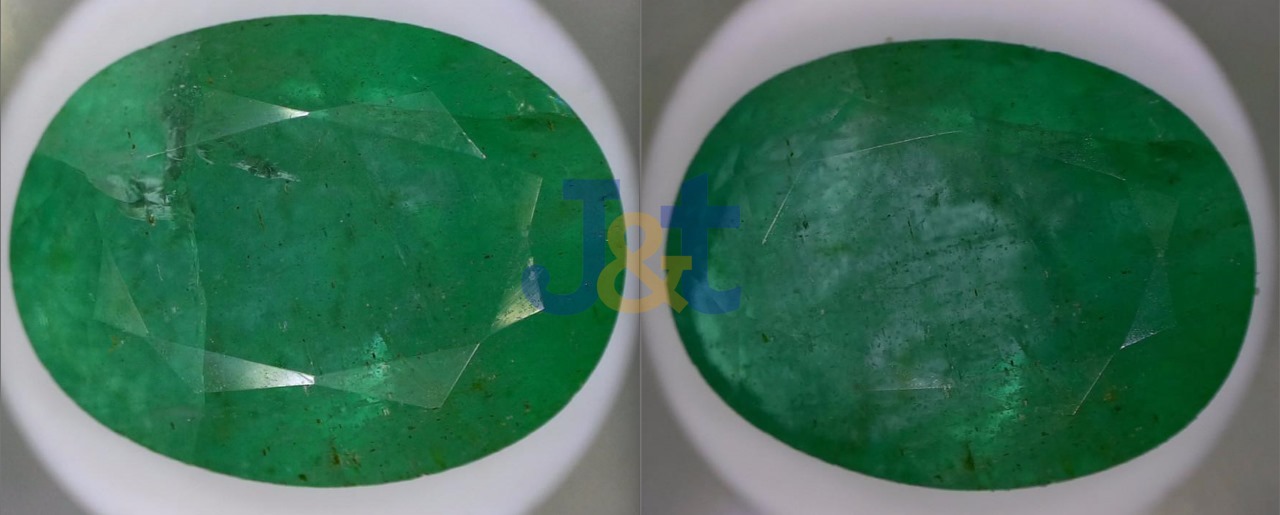

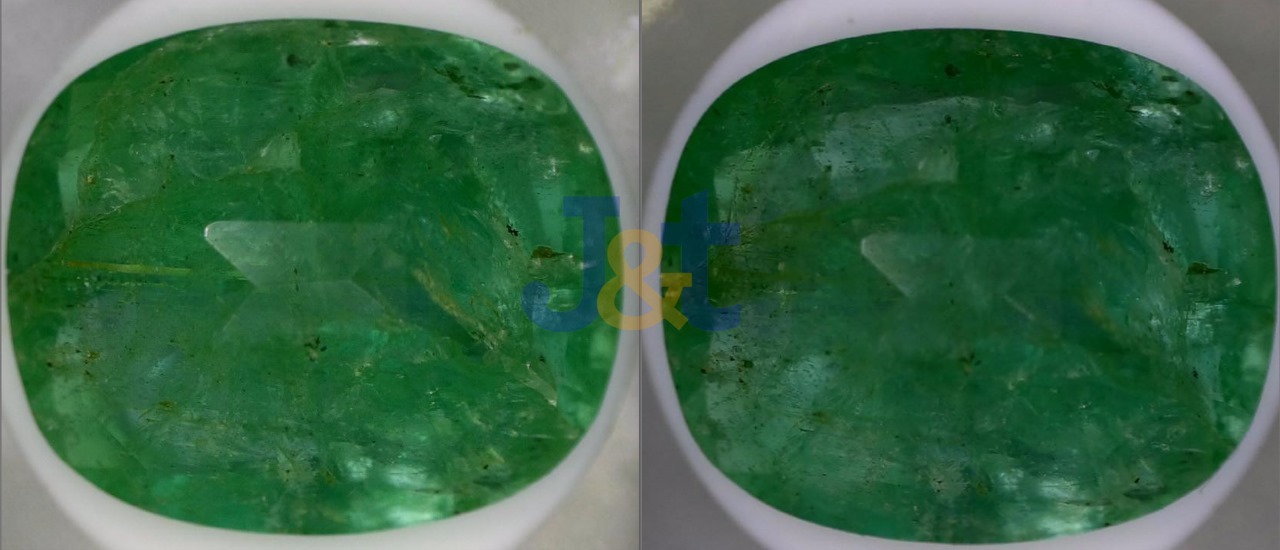

Before & After Results

The following before and after images of Emeralds are unedited. We photographed them under the same lighting conditions and at 10X magnification to show the true effect of treatment.

FAQs

Does the machine include a vacuum pump?

Oiling + Resin variant of the machine includes a 2-stage 1/4 hp vacuum pump and an acrylic resin lid with valve and vacuum gauge. Oiling-Only does not include these accessories.

What temperature should I set?

Typical temperature range for gemstones like Emeralds is 60°C to 80°C. The system is locked in to support up to 100 °C. Select temperature and time depending on the oil/resin used and stone characteristics, following the SOP guide.

How do I control the pressure of the machine?

Pressure is not set directly; it’s created when the oil expands under heat in the sealed chamber. The target temperature you set on the controller (e.g., ~75 °C for cedarwood oil with emeralds) determines how much the oil expands, and thus how much pressure builds inside. Therefore, it depends on the characteristics of the oil and the target temperature.

Which stones can be treated?

Emeralds are the most common. Other porous or fractured stones can be treated after testing to confirm compatibility with oil or resin.

How big is the chamber?

The chamber is ~140 ml (65 mm × 52 mm), suitable for small-to-medium batches.

How many stones or carats can be treated at once?

The average working capacity is about 400 carats per batch, depending on the size of the stones. For small emeralds (2–5 ct), this can be 80–150 stones, while larger stones reduce the count accordingly.

Why do some gemstones show better improvement from oiling/resin treatment than others?

There can be multiple factors. Results vary mainly due to:

- Stone characteristics – Dark inclusions or non-fracture inclusions (like pyrite or growth tubes) cannot be improved by oil/resin filling.

- Fracture type – Open, surface-reaching fractures accept oil/resin easily. Tight or sealed fractures do not.

- Cleaning quality – Any leftover oil, moisture, or polishing debris blocks oil/resin penetration.

Stones with open, clean fractures that are well dried and treated under stable pressure/vacuum + correct heat will always show the best clarity enhancement

Warranty & Support

- 1-year standard manufacturer warranty on the machine

- Supplies and consumables (O-rings, seals, oil/resin, etc.) are not covered under warranty

- After-sales service with spare parts availability and process guidance

- Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

International Customers & Shipping

- For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

- Our logistics partners are DHL & FedEx. If any of these have operations in your country, we should be able to ship the products to you.

- The shipping of this faceting machine is insured.

- Time for shipping varies depending on the shipping region, but usually, it takes no more than 10 business days to be delivered anywhere in the world, once it’s dispatched. The dispatch times vary depending on stock availability.